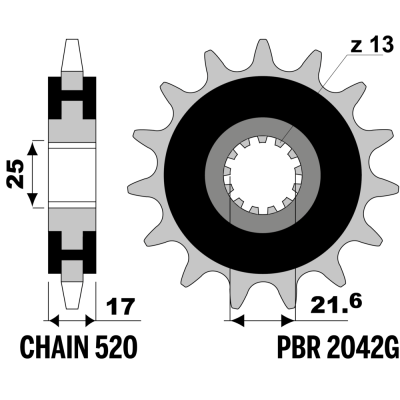

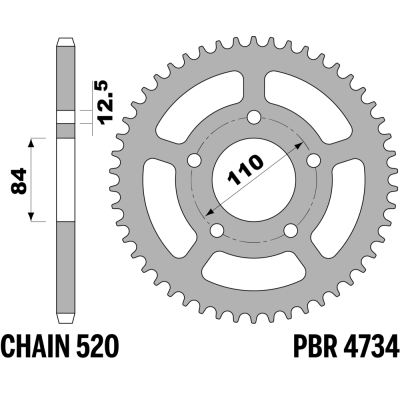

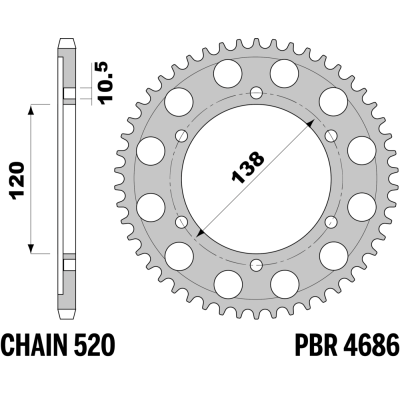

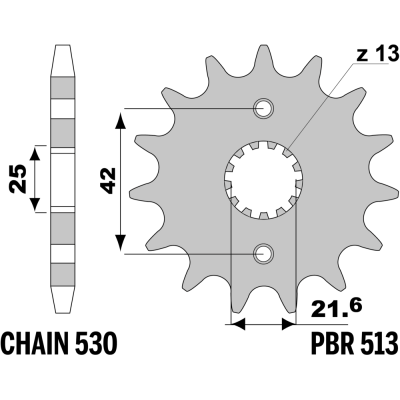

List of products by brand PBR Sprockets

Italian manufacturer of crowns, pinions, chains and handlebars for motorcycles

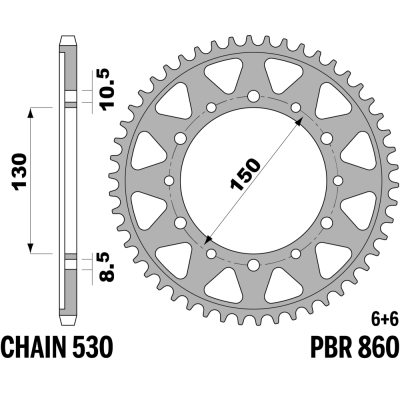

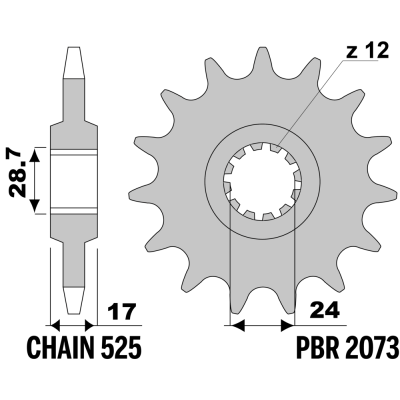

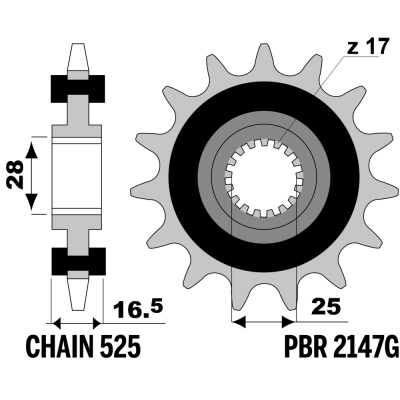

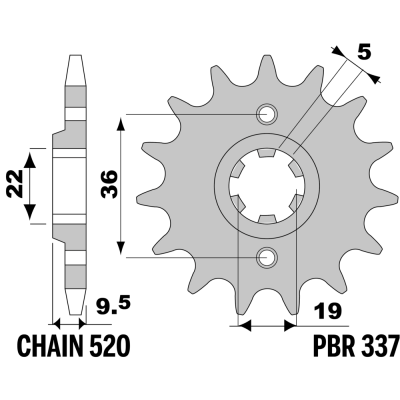

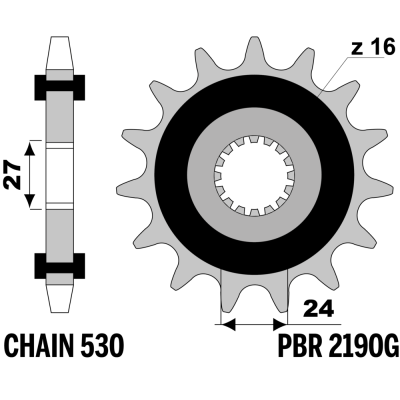

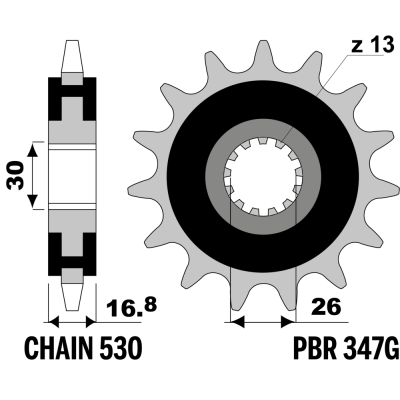

Since 1969, the year when Bruno Palladino had started the production of front and rear sprockets, the PBR company has been in constant technical and commercial growth. In 1973 the company from Bologna extended the production to the after market, concentrated exclusively on the motorcycle market and started the collaboration with a lot of italian constructors as Benelli, Moto Guzzi and Malaguti. Following directly the pilots during the cross racings, getting important experiences it was next step for PBR to develop its products of high reliability level which helps us to respond to the highest competition requests. In this way, PBR started the collaboration with Aprilia in that time working also on off-road, Ducati, Betamotor, Bimota, Husaberg, Laverda, Honda, TM, Polini, BMW suppling the street and off-road products and expanding in the same time the range to the minimoto, kart and maximoto. The succes is due to a particular use of only the high quality materials, resistant to abrasion or corrosion like carbon steel C45 or 18NCD5 when the other manufacturers were using traditional materials as well as to valid advises of collaborators like Puzar, Jobè, Chiodi, Nilsson, Rinaldi, Ahvala, Gresini who had contributed to the developement of innovative front and rear sprockets. The PBR products made another quality step with participation in the Superbike competitions when for three years had already been working with Endough Team, Sport Production and Monomarca Teams. A further step to grow the quality is posivite answer of the worldwide wholesalers, the export sale and constant request of international market for USA, Japan, South America and Africa, Australia and New Zealand which helped us to understand and resolve problems, to confront with new, different realites and improve the product also from the estetic point of vue. The rear PBR sprockets are made of steel sheet, special carbon steel C45 or alloy Ergal 7075 T6 according to a grade of duration and lightness requested. First the sheets are sheared by the press and then, in case of alloy, worked on turning-lathe with digital control to be finished in one operation. For the steel we use half-automatic machines in multiple working cycle, after that there is a toothing process and at the end final control and finish. The front sprockets are manufactured from the bars cut and then machined on special turning-lathes with digital control which finishes a piece by its own and doesn't request an operator's presence. The cycle is closed in the same way with toothing, final control and finish. The results of this growing experience in the past years is the quality certification and a save product of superior quality.